Lead image: Smiling Eliud – brought to you by Quinn Harris/Getty

As a young, hopeful exercise science student (with a real penchant for athletic footwear) – I stumbled into the classic trope of studying myself into a niche. I flew headfirst down the rabbit hole, taking on a masters in the field of sports engineering – a materials engineering degree with a research based twist at RMIT.

As a middling club athlete, I’d always been fascinated by the process of prototyping footwear, and the secrecy that surrounded product testing and patenting. Eventually leading me to corners of the internet far nerdier than mere LetsRun message boards. A perk of this masters degree was a series of footwear specific subjects, combined with various subjects that intertwined with carbon fibre and its rapid development in additive manufacturing.

As last weekend delivered two drastic parameter altering marathon performances, the capable feet of Eliud Kipchoge and Brigid Kosgei sent the collective twittersphere into a meltdown of sorts. A potent mix of well informed scientists and engineers, coupled with furious running journalists and fans who hadn’t quite grasped the technical aspects of the shoe ‘arms race’. With cries of ‘cheating’ being thrown around all over the shop, I fired up an old group chat with a few uni mates and revisited a few concepts from years gone by, brushing up in preparation for this footwear Mother Theresa exercise.

What lies below fits neatly into three buckets:

- What is this mysterious formula one inspired ‘carbon fibre’?

- The current footwear market state – prototypes and all

- What beckons on the horizon of the secretive footwear world

Whilst I’d encourage a full reading, I’m sure you’ve all got lives to lead – thus, feel free to jump to the section that entertains you most.

Carbon fibre – what is it?

As a sometimes applied student, it’s important here to provide a few expert definitions, whilst chiming in with a translation or two.

Our more than capable Commonwealth Scientific and Industrial Research Organisation (CSIRO) has the following to say:

“Carbon fibre (CF) combines high rigidity, tensile strength and chemical resistance with low weight. It’s increasingly being used across industries such as aerospace, automotive, oil and gas, clean energy and sporting goods to replace traditional materials like steel and aluminium.”

Translation: incredibly light, very difficult to bend, retains original shape under any sort of pressure humans can exert through their feet, providing the same response through repeated impact phases.

This is a market expected to be worth roughly $31b, by 2024 – athletic footwear is the tip of the iceberg in this industry, planes, trains and automobiles are the industry drivers.

As space age as this substance sounds, the first noted use of CF took place in 1860, with a mass production use of the fibre in 1946 by car manufacturer DuPont. Thus, everyone take a deep breath – note this substance didn’t pop up in 2016 for evil apparel overlords to wreak havoc on the marathon with (but, more on that later).

A brief ode to any keen science kids – the thing about CF that had me hooked from mention one – it’s an initially spun substance – yes, much like a thread. The fibres are incredibly small, usually 5-10 microns in diameter, the same department as spider web silk. The major difference with that pesky spider web you walk through in the morning followed by squeals and flailing… CF is twice as stiff as steel, whilst being five times as strong.

To reiterate, one micron = 0.0001 cm – bends the noggin’ a bit, right?

CF is created largely through spinning a precursor (polyacrylonitrile, or PAN) with other chemicals to create a fibre, following by chemical stabilisation procedures, carbonizing (more bonding through extreme temperatures… essentially – cooking!), further chemical treatment to encourage bonding, then sizing of raw product.

Why is it used in running footwear? In extreme summary, it is incredibly stiff, doesn’t expand under heat produced by the human foot or shoe, whilst retaining original dimensions for substantial periods of time under human compression – it also straightens your toes.. (for more info on that peculiar nugget, onward!)

The Marketing Debacle vs Science

Throughout my days wandering uni halls, largely lost and slightly late to tutorials, there was one phrase that drew immediate fury from an Austrian professor – “energy return” – one of the most used, least understood marketing phrases in modern footwear to date. Why does this phrase infuriate the physics & engineering brigades?

It does not currently exist in mass marketed footwear.

Many years ago, Adidas produced an amusing advertisement, where a steel ball bearing is dropped onto a piece of proprietary foam, and the ball rockets into the air – to a far higher height than initially dropped from. Anyone who has been tortured through a postgraduate physics class will flinch immediately, due to one pesky little principle known as the ‘coefficient of restitution’, which renders the suggested steel to foam collision response extremely unlikely.

The coefficient of restitution is the ratio of the final to initial relative velocity between two objects after they collide – ranging from 0 to 1 (1 = an entirely elastic collision) – this occurs in your feet when they thud into the ground. Energy ‘return’ suggests you are receiving more energy each step than you have initially imparted upon the ground… to generalise – this is impossible in mass marketed shoes.

Why?

Because your shoes aren’t shaped like an AFL ball.

As our weathered physics professor regularly joked, the only object that creates its own energy return, is an oblong shaped AFL footy – as it bounces end over end a few times, generating kinetic energy, then pops up slightly higher on the third or fourth rotation.

So what do shoes really deliver you?

Dissipation: Effectively, shoes minimise your loss of energy during landing through initial translational kinetic energy loss due to rotational kinetic energy, plastic deformation and heat – substantially more so through a dirty great big CF plate.

The footwear market is a multi-billion dollar economy – thus a slip of the tongue between ‘energy return’ and ‘dissipation’ is seen as a small scientific loss, however the effects substantial changes in dissipation have on running economy are staggering. The changes brought upon the market since 2016 through proprietary CF and pebax (shoe plastic material of choice) are truly staggering.

Running Economy: The what & why

A well documented determinant of running performance, running economy is defined as – “The steady-state oxygen consumption (VO2) at a given running velocity, which is often referred to as running economy (RE), reflects the energy demand of running at a constant submaximal speed.” (2015, Barnes & Kilding)

Translation: how much oxygen you utilise ticking along at a manageable race pace, below lactate threshold.

RE is a complex concept that takes factors from metabolic, cardiorespiratory, biomechanical and neuromuscular buckets – however, can be improved through specific footwear interventions. Here is where our good friend CF absolutely obliterates the ‘normal’ parameters for athletic improvement.

When an athlete begins to fatigue, RE drops, a phenomenon many runner could associate simply with biomechanics – once fatigued, a noticeable decline in coordination occurs.

In utilising footwear which contains an extremely stiff sole plate, there is a material constant that doesn’t tire, retaining response and original shape on each step. Effectively, any shoe with a midsole has a ‘spring’ – however the growing controversy around the interpretation of a ‘spring’ or ‘propulsive’ insert focuses on simply how much ‘springier’ such an insert makes a shoe.

A substantial alteration in conventional foot land and toe-off processes is the effect of a curved CF plate straightening an athletes toes. During initial research conducted by University of Calgary researcher Darren Stefanyshyn in 2006 (source – original Alex Hutchinson article from Outside Online – highly recommend), Stefanyshyn noted that similar investigations had been conducted throughout the 1990’s (Adidas ‘ProPlate’), with Brooks claiming studies on the concept in the 1980’s. Whilst running, you expend energy bending and straightening your toe joints, which aren’t as elastic as your ankles or foot arch – which snap back into place throughout a step. Your humble toe joints are particularly wasteful.

If you were to search a variety of Nike footwear patents, or cast your eyes on a pair of prototype spikes – one name pops up with regularity – Geng Luo. A footwear chef of sorts, Luo was a PhD student of Stefanyshyn – responsible in part for the aggressive curve in the CF plates patented by Nike. This aggressive curve negates the additional energy costs at the ankle joint brought on by straightened toes, retaining various RE benefits.

One of the most important distinctions made superbly by Alex Hutchinson in Outside Online, is the relationship between Nike’s proprietary foam and plate. Both innovations are useful, however when combined, they are a force to be reckoned with. Footwear brands have begun to utilise Pebax, a material much like CF, where a large footwear company cooks up a proprietary mixture of their own.

The combination of an extremely stiff, responsive CF insert, and a foam that depresses and reacts rapidly to an original shape appears to be the magic mix. Hutchinson is an established author on a variety of scientific topics, and notes whilst summarising a variety of research papers on the topic, scientists have lengthily responded: “They’re not sure what’s going on”. Additionally there is a biomechanical theory that suggests the shoe stack height and foam/plate mix changes the ‘gear ratio’ that exists between your limbs, shoes and joints (source).

There topic has spurned multiple academic articles & two in-house Nike research papers – of which I will attempt to list as many as possible of at the base of this article. The above exists to outline the base concept of foam plus CF plate shoes.

The takeaway from this information is that this new type of footwear works – repeatedly improving athlete RE. This concept is not consistently linear in terms of a race time improvement, with Nike estimates in RE improvements as high as 4-5% – the most conservative independent research indicates 0.8-1% improvements in RE.

Many punters query at this point – “What’s 1%? That’s negligible”

In a 2:03:00 marathon, the following time to performance improvements may occur:

– 0.8% = 59.04 seconds

– 1% = 73.80 seconds

Thus lurks the uncomfortable question – are we seeing 2010-2015 athletes in 2016-2020 footwear? Or has there been an immense improvement in marathoner ability worldwide?

Many minds far wiser than mine suggest this improvement is complex and involves a variety of variables – yet the agreement on improved performance via footwear technology development is unanimous.

My motivation to summarise a few key points was built from changing the narrative – this is not a single company industry. Below are the current plethora of examples available both commercially and unavailable prototypes that have ‘leaked’.

Substantial imaging credit to Rolows (twitter/instagram) & tracktalk.net (a surviving sliver of the old Dyestat boards).

Nike

The original CF plate/VF 1: Even in a heavily worn pair of the original VF’s, the plate remains a distinctive shape & aggressive curvature.

VF Next%: The most current commercially available VF iteration

Nike “AlphaFly”: Apparently worn by Eliud Kipchoge in the INEOS 1:59 attempt (various industry folk have suggested Kipchoge receives a pair tweaked substantially from patent documents) – the peculiar fluid filled bags at the base of the shoe have sparked substantial interest – more on that later in the patents section.

Hoka One One: Early adopters of maximalism, slightly later adopters of CF plate technology, a few options became available in 2019 – albeit minus the marketing hype Nike capitalised on rather lucratively.

Hoka Carbon Rocket

Hoka Carbon X: Greater stack height, CF plate included.

New Balance: Less attentive running fans might’ve assumed NB weren’t coming to the CF plate party – false. A road mile racing flat exists, as does a marathon prototype. Those with a particularly keen eye would’ve noticed NB stars Emma Coburn & Jake Wightman wearing what appear to be CF plated spikes also (a more established trend in track racing.

NB FuelCell 5280: Early prototypes (2018)

NB FuelCell 5280: Final Product

NB early 2019 Marathon prototype: A marathon option with stack height

A more polished prototype: feat. Callum Hawkins in Doha

A CF plate spike in Doha: worn by Coburn/Wightman with slightly differing uppers

Asics: Inside the last month, an all black option has appeared – with mixed reports from Asics athletes – Jan Frodeno described the shoe as having a carbon fibre plate, whereas Sara Hall suggested the shoe was sans plate but had a rocker of sorts.

Frodeno described the new shoe as such a recent prototype, that the logo was hand-painted on – as the up close lateral view appears to mirror, with paint deteriorating at the logo base. Said shoe carried Frodeno to a Kona Ironman victory and course record.

Mizuno: A typically Japan-centric product line of racing flats (with many items simply not available outside of Japan) – an all white thick-soled prototype appeared at last week’s Izumo Ekiden.

Skechers: A variety of reports have surfaced regarding the latest offering from the US brand, with suggestions of a new foam and/or a plate of sorts – the current “Gomeb Speed 6 Hyper” (as per the invaluable Rolows13) – apparently contains a nylon plate, with a variety of in-house foams. A plated version is slated for a February 2020 release.

Brooks: One of the earliest testers of the CF plate concept, not to be forgotten, have tested a black out chunky sole option since 2018.

Not a great deal is known about the Brooks option, merely that it does contain a CF plate.

Li-Ning: Apparently this shoe takes err, ‘inspiration’, from a variety of current market options, feel free to make your own mind up on this one.

Saucony: A substantially taller than usual sole has appeared on a variety of Saucony professionals lately, barring Molly Huddle, who has yet to openly race in the CF plate prototype.

Adidas: A curious case of resistance – with zero apparent CF plated prototypes in the works – the previous Saucony image depicts one of two Adidas prototypes that have popped up without a name. Coupled with the image below of a newer lightweight racing flat in apparent testing, the midsole appears slightly built up, but without substantive athlete interviews or brand admissions of CF plate testing, it remains difficult to know where Adidas sit on this growing trend. It would be remiss to assume Adidas don’t have a CF plate racing flat ready to rumble for 2020.

The 2019-20 pipeline and beyond: the magic of the US patent office

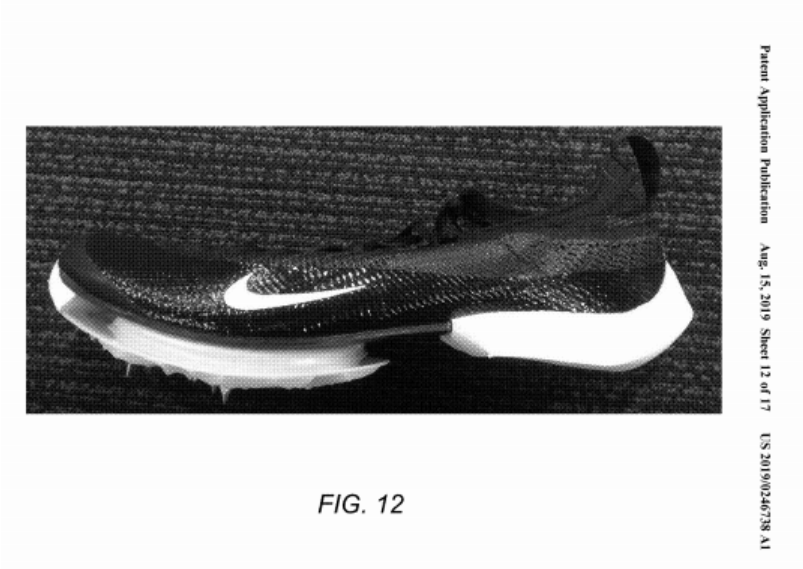

As inferred previously, the mixing of proprietary foam and CF isn’t exclusive to the road racing circuit – behold, the latest in the Nike development line.

The footwear world’s collective brain did a 720 degree spin of sorts upon seeing these spikes unveiled on the highest profile Nike athletes at the IAAF World Championships.

Largely due to the somewhat home-brand difference an apparent piece of masking tape made to early 2019 prototypes.

Reaction: roughly this…

Nike’s veracity of patenting and rate of development creates a fun year-round game for footwear nerds to track. As more significant meets roll around each year, a small cluster of athletes are likely to be wearing something folks haven’t seen outside of leaked training group photos.

One way to circumvent the information cycle involves a visit to Google Scholar & the US patent office – shedding substantially more light on Nike’s newest spiked creations…

US Patent Office: Where information first lands

If an individual set a google alert or three on a group of key footwear inventors, information regarding incoming footwear becomes somewhat easier to source. The US patenting process is a race to ensure intellectual property is recognised, with brands marking territory years before retail products come to light.

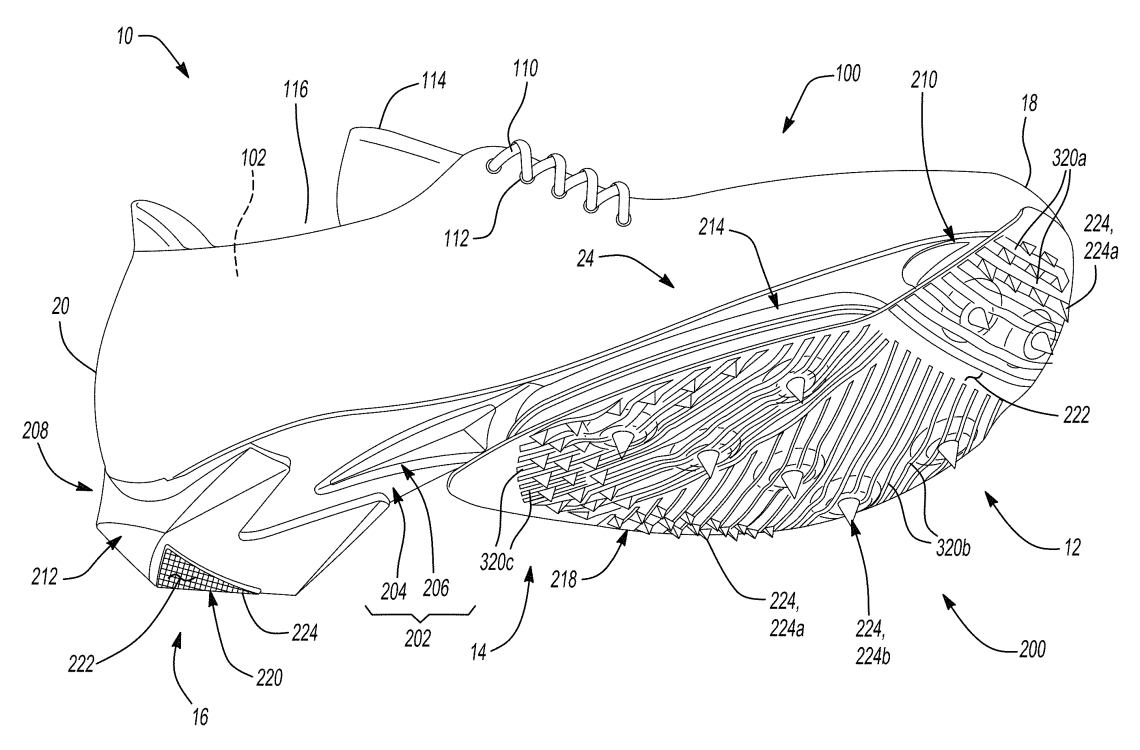

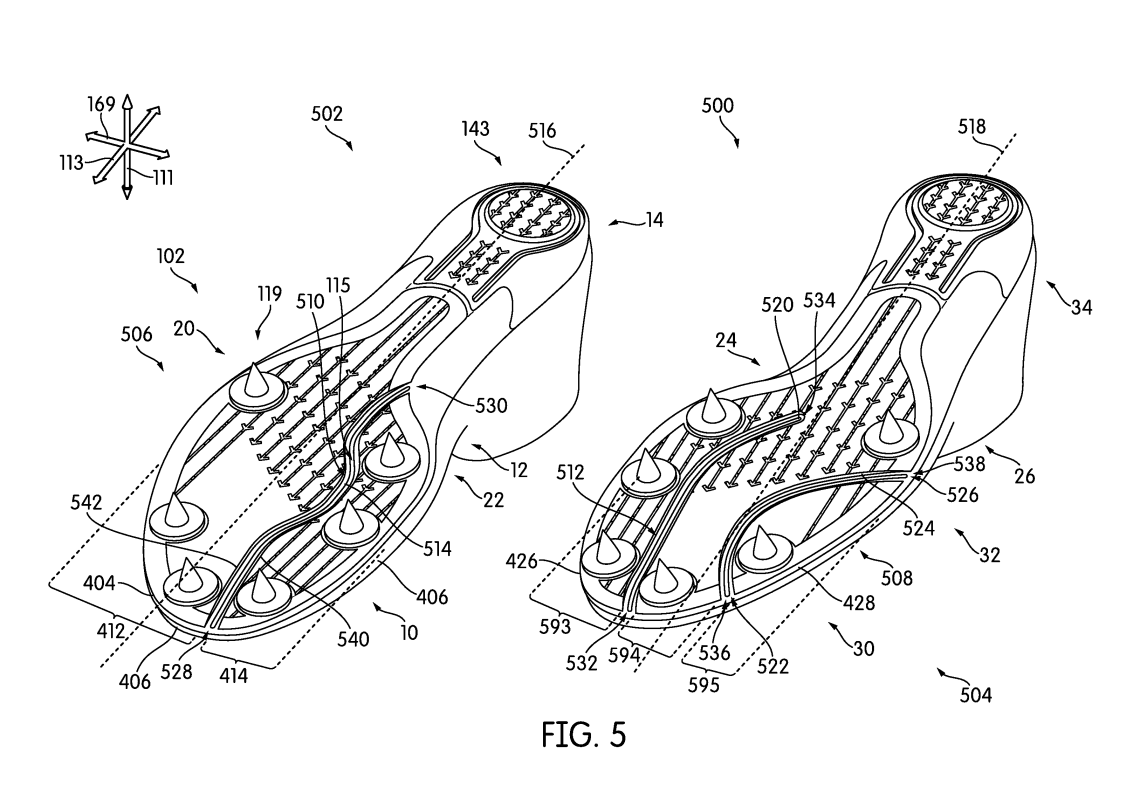

Note: these documents are lengthy in the extreme – images listed in patent documents have small arrows and numbers – if a piece of a shoe looks particularly interesting, find the corresponding number and have a read!

A few notable patents from Nike our previously mentioned footwear chef Geng Luo include: (If I knew of competing brands footwear developers/hadn’t spent many nights on this treatise, I’d have included them!)

“Footwear sole structure including a spring plate” (2015) https://patentimages.storage.googleapis.com/17/1a/5e/5fdd1da73283af/WO2016179265A1.pdf

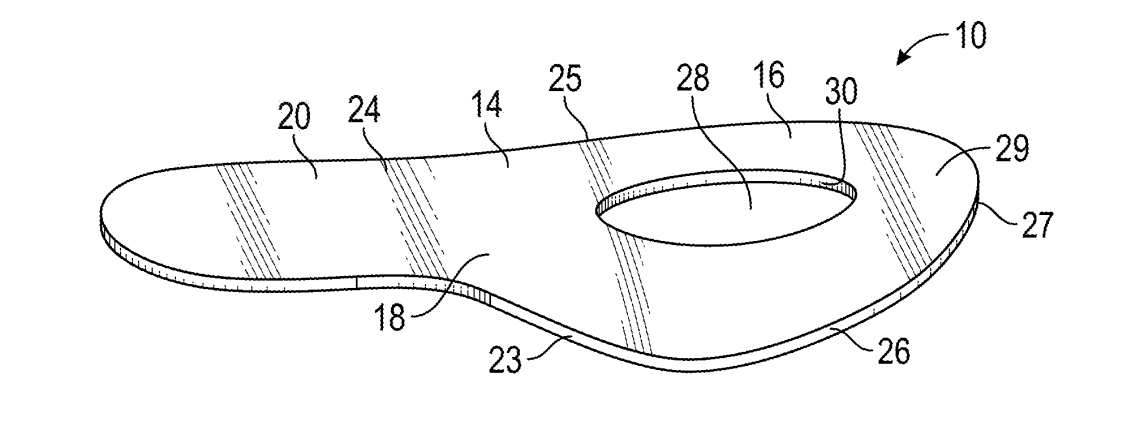

Whilst the public never saw the finished product this patent pointed toward, it was the initial indicator that Nike were wandering ever closer to the CF plate world – making specific remarks to the effects a plate had on regions of the foot. The initial wording of this patent does stir a few “it can’t be a spring” folks up. The following section raised plenty of eyebrows at the thought of having an internal CF plate that could be removed or modified at will – “The spring plate may comprise an open central region defined by a surrounding band and may be non-destructively removable from and replaceable into the upper.”

“Sole structure for article of footwear” (2018 – images edited in during 2019)

https://patentimages.storage.googleapis.com/ca/d9/bb/cf3c290e628444/US20190246738A1.pdf?fbclid=IwAR2DL5lhxlMDCAGEPHpH_WE84N69qW0aKjlxvjfiNp2zH3kEHm8v0YOigzY

One of the earliest images of the spikes unveiled in Doha – the patent contains plenty of fascinating tidbits regarding the ways in which the CF plate and fluid filled ‘bags’ of sorts work in tandem. The patent extensively details why single piece polymer soles are problematic, forcing the manufacturer to make a decision between performance and comfort with the density of a sole effecting how athlete load is managed across a variety of gradients. In this instance, Nike have squeezed four sections together, working toward a mix of comfort and performance.

The concept of pressurised air isn’t particularly new to running shoes, however it is an interesting addition to middle distance racing spikes. The air/fluid bags resist compression, whilst the CF plate stiffens the entire process and dissipates force.

“Asymmetrical segmented plates” (2017)

Click to access US20170196305A1.pdf

Many a shoe nerd theorised this would be Nike’s next big thing – plates designed specifically for the demands of running in a strange oval shape – the crux of the sport! With specific sole differences such as ‘split toe’ plate featuring grooves which aimed to reallocate pressure placed on the foot whilst running a bend at pace, this delightful concept never saw mass production, but got imagination’s ticking nonetheless.

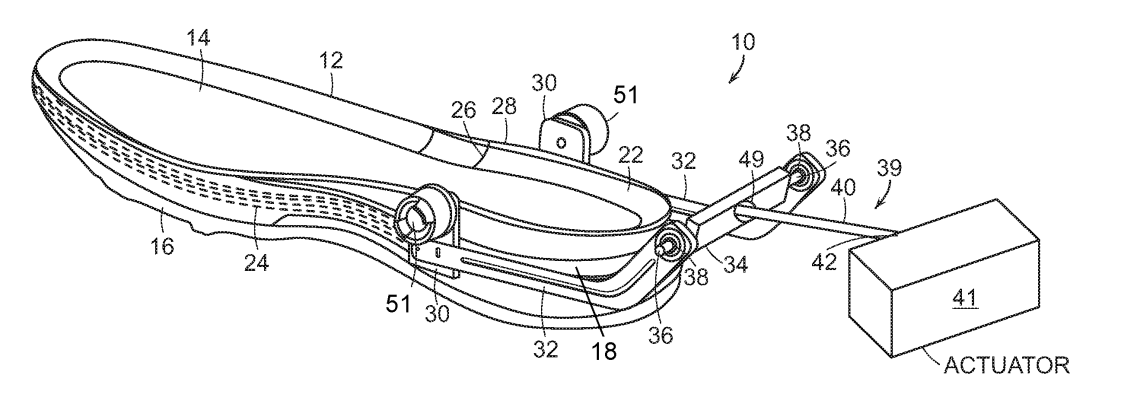

“Method and apparatus for dynamically altering a height of a sole assembly” (Filed 2017 – images edited up to 2019)

Click to access US10426221.pdf

Worth a quick flick through – effectively, Nike have considered a 4%/Next% type sole that can be altered in stack height through wedges or pressurised bladders. Yes, footwear companies are an entire postcode ahead of whatever pondering you’ve likely attempted.

“Energy return footwear plate”

https://patentimages.storage.googleapis.com/b1/f3/76/a9bcf12ee83fd5/US20180168281A1.pdf

A plate… with a gap in the centre? A plate shape differing drastically from what is currently available, many a scientist would be eager to investigate the biomechnical and performance differences derived from a plate extending to the edge of the foot, with a hole of sorts in the main foot strike region.

If anyone has ventured this far, I appreciate the effort. In the most extreme of generalisations, this is a market which will see professional regulation of sorts, it is highly likely stack height, plate stiffness or torque limits are introduced. This is an exciting new intersection between technology and performance footwear, fans should welcome it, learn about it, and develop a greater understanding of the aims of these performance innovators prior to brandishing criticisms. With the plethora of brands involved this market doesn’t appear to be one set to grind to a halt.

Encouraging disclaimer of sorts: this topic is absolutely immense, there are tens of articles and patents I could’ve speculated upon – I’d encourage anyone with an interest in footwear to dig deeper across the wonderful web for more specific analysis. Whilst this has ended up quite a lengthy exercise, it would’ve been painfully long if any attempt was made to include ‘all’ relevant info.

Thus, look below!

Further reading

A breakdown of the AlphaFly patent: https://www.believeintherun.com/2019/10/09/a-breakdown-of-the-nike-kipchoge-prototype/

Alex Hutchinson (fantastic contributions): https://www.outsideonline.com/2400514/nike-vaporfly-carbon-plate-presentation

https://www.outsideonline.com/2367961/how-do-nikes-vaporfly-4-shoes-actually-work

Is it the shoes? A simple proposal for regulating footwear in road running: https://bjsm.bmj.com/content/early/2019/10/18/bjsports-2018-100480